The craft of brewing beer melds ancient tradition with scientific precision, embodying a rich history that spans thousands of years.

This guide, “How Beer is Made: From Ingredients to Fermentation,” delves into the essential elements—water, malt, hops, and yeast—that define a beer’s character.

Each ingredient impacts the flavor, aroma, and texture of the final product, making the brewing process a delicate balance of art and science.

From the initial mashing step to the final fermentation, every stage is crucial in transforming simple ingredients into complex beers enjoyed worldwide.

This introduction offers a concise overview, setting the stage for a deeper exploration of the artful process of beer production.

How Beer is Made: From Ingredients to Fermentation

The art of brewing beer is a fascinating journey that transforms simple ingredients into a diverse range of flavorful beverages. Understanding these key ingredients – water, malt, hops, and yeast – and the brewing process itself unlocks the secrets behind the vast spectrum of beer styles we enjoy today. This guide delves into the magic behind beer making, exploring each ingredient’s role and its impact on the final product.

The Essential Building Blocks:

Water

Often overlooked, water makes up a whopping 90-95% of beer! Its mineral content, like calcium and magnesium, significantly influences taste and texture. Soft water regions favor crisp lagers, while hard water areas might be known for their hoppy pale ales.

Malt

The foundation of flavor and body, malt provides the sugars that fuel fermentation. Typically made from barley, malt can also come from wheat, rye, or oats, each adding unique characteristics. The malting process involves sprouting the grains to develop enzymes that convert starches into fermentable sugars.

Hops

These little green cones are the rockstars of bitterness and aroma. Different hop varieties contribute a spectrum of flavors, from citrusy and floral to spicy and earthy. Hops also act as a natural preservative, extending the shelf life of your favorite brew.

Yeast

The unsung hero, yeast is the tiny organism that converts malt sugars into alcohol and carbon dioxide, causing fermentation. There are two main types: ale yeast (think fruity, spicy beers) ferments at warmer temperatures, while lager yeast (known for crispness) thrives in cooler environments. The choice of yeast plays a big role in the final beer’s flavor profile, clarity, and alcohol content.

By understanding these key ingredients and their fascinating interplay, you’ll gain a deeper appreciation for the artistry and science behind every delicious sip of beer. The next sections will explore the brewing process itself, taking you on a step-by-step journey from mashing the grains to fermentation and beyond!

The Brewing Process

We’ve explored the essential building blocks – water, malt, hops, and yeast – that form the foundation of every beer. Now, let’s delve into the fascinating journey these ingredients take, transforming them into the delicious beverages we enjoy. Buckle up for a step-by-step adventure through the brewing process!

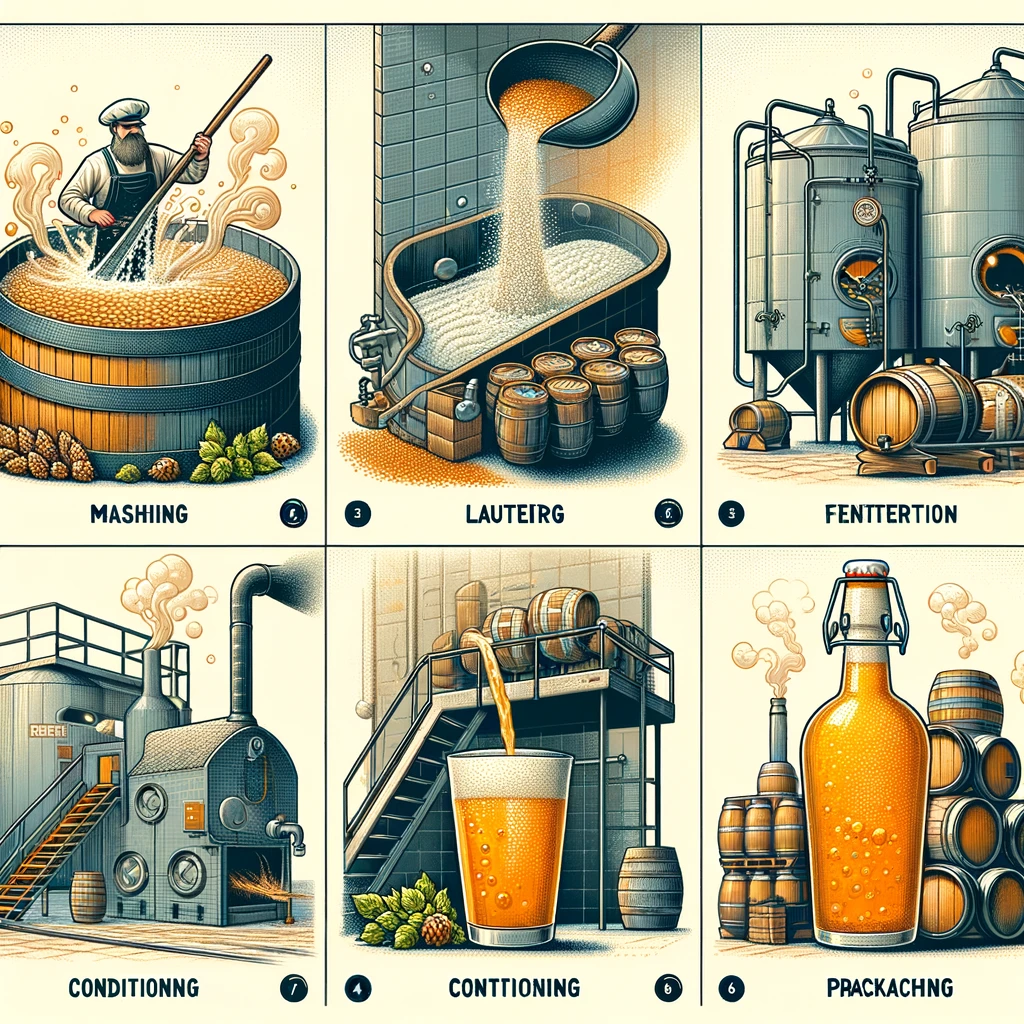

The Brewing Alchemy:

Mashing

The magic begins here! Crushed malt is steeped in hot water, activating enzymes that convert the starches into fermentable sugars – the food source for our yeast rockstars. This sweet liquid is called wort.

Lautering

After steeping, the wort is separated from the spent grain husks in a process called lautering. Imagine a giant colander separating the flavorful liquid from the solids!

Boiling

The wort gets a good boil, which serves a dual purpose. First, it sterilizes the liquid, ensuring a clean fermentation. Second, it’s hop addition time! Hops are introduced at various stages of the boil, contributing bitterness, and aroma, and acting as a natural preservative.

Fermentation

This is where the real party starts! Yeast is pitched into the cooled wort, and the magic of fermentation begins. The yeast devours the sugars produced during mashing, converting them into alcohol and carbon dioxide – the key components that define a beer’s character.

Conditioning

After fermentation, the young beer undergoes a conditioning period. This allows time for flavors to mature, CO2 to naturally carbonate the beverage, and any remaining yeast to settle out, resulting in a clear and crisp beer.

Packaging: The final step! The finished beer is packaged into bottles, kegs, or cans, ready to be enjoyed by beer enthusiasts everywhere.

We’ve traversed the exciting journey from water, malt, hops, and yeast to the finished product through the core brewing process. But the art of brewing goes even deeper! Let’s explore some fascinating variations in brewing techniques:

Different Brewing Techniques: Traditional vs. Modern, Home vs. Commercial

Traditional vs. Modern Brewing Techniques

Traditional brewing methods are deeply rooted in cultural histories and often involve hand-crafted techniques passed down through generations. These methods typically rely on local ingredients and may use spontaneous fermentation.

In contrast, modern brewing embraces technological advancements, such as precise temperature controls and automated systems, which enhance consistency and efficiency. Modern techniques also allow for innovation, such as the use of novel ingredients and experimentation with fermentation processes.

Home Brewing vs. Commercial Brewing Practices

Home brewing is a popular hobby that allows individuals to experiment with creative recipes on a small scale. Home brewers enjoy the flexibility to tweak every aspect of their brew, from the malt profile to the type of yeast used, often leading to unique and personalized beers.

Commercial brewing, however, is geared towards mass production, focusing on consistency, scalability, and meeting regulatory standards. Commercial breweries invest in sophisticated equipment to control large batches and maintain flavor profiles across different brewing cycles.

Conclusion

In summary, the journey of beer from ingredients to fermentation encompasses several crucial steps: mashing, lautering, boiling, fermenting, conditioning, and packaging.

Each stage plays a pivotal role in shaping the beer’s final character, from the sweetness of the malt to the bitterness of the hops and the complex flavors introduced by fermentation. This intricate process highlights the art and science behind brewing, where precision and creativity go hand in hand.

Experimenting with different brewing techniques—whether traditional or modern, homebrewed or commercially produced—can deepen your appreciation of beer and inspire a greater connection to this ancient craft. Dive into the diverse world of beer to discover new tastes and experiences that await in every bottle.

Harold Desir is a seasoned beer enthusiast and expert, with over a decade of experience exploring the world of craft beers and brewing techniques. His deep knowledge of beer styles, brewing processes, and industry trends makes him a trusted voice in the beer community. Harold's passion for all things beer is evident in his engaging and informative blog posts, where he shares his insights, reviews, and tips with fellow beer lovers. Cheers!